Frameless glass balustrades

Frameless glass balustrades are also called structural or cantilevered balustrades. Most of the structural strength of these types of balustrades comes from the glass itself. Since there are usually no posts of handrails, is very crucial for the glass panels to be strong.

Frameless glass balustrades are used on external balconies, internal level changes, or staircases with various fixing techniques to match the surrounding elements. They are also integrated into several aluminum door frames to create a minimal Juliette Balcony.

The ideal glass panel type for a frameless balustrade is toughened laminated glass with a minimum thickness of 15 mm for residential and 19 mm for industrial setups.

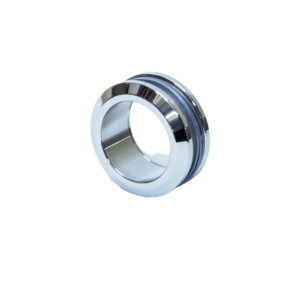

In addition to the strength of the glass, the support and structural strength come from base fittings or shoe profiles. In simpler words, these are U channels that the glass panels are securely fixed into, using either a strong epoxy glue, a special type of cement, pressure-screwed clamps, or hammered-in wedges.

The base is fixed in the building structure by appropriate means after a thorough assessment of the site and the fittings used.

As a leading commercial glass supplier in Kenya, Impala Glass offers a wide choice when it comes to glass balustrade systems. Our experts can help you at every stage of the process, from the design to the supply and the installation of your glass balustrade.

Some key notes on the fixings for the glass balustrades:

While choosing any type of fitting, keep in mind the glass specification, location of the balustrade, project type, and building construction.

For a clearer idea, let us explain this. For over slab fixing, the balustrades is fixed at the top of the surface with a 124.5 mm fixing that is bolted down on the balustrade for extra support and strength. This method of fixing is ideal for a setup where a channel for water to flow is required. It can withstand weight up to 3kN.

Another type of fixing is offset over slab fixing. It is installed in a similar method, however, the fixing is bolted down into the slab below through a fixing on the inward-facing side of the balustrade.

Some of the balustrade fixing options are:

- Channel Fixing for Balustrades: for this type of fixing the toughened laminated structural glass balustrade is fixed into a prepared and purpose built balustrade channel. This channel is designed to be installed below finished floor level for a frameless balustrade design.

- Bolt Fixing for Balustrades: A bolt fixing design is generally used where a glass balustrade is requirement to be fixed to the outside of a structure, for example staircases.

- Bolted/Clamping Plate Fixing for Balustrades: for a structure that requires balustrades 1.1m or highrer, the best option is bolted plate or clamping plate fixing detail. This is a surface mounted balustrade fixing method. Here a steel fixing plate is fixed to the surface of the balustrade with countersunk fixing bolts.

Now that you know the basics of glass balustrades and the fittings required for it, call Impala fitting for best services and products.